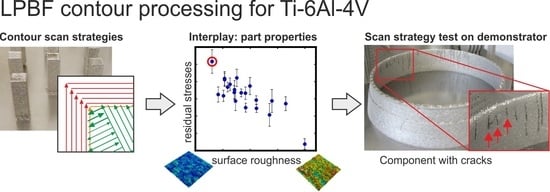

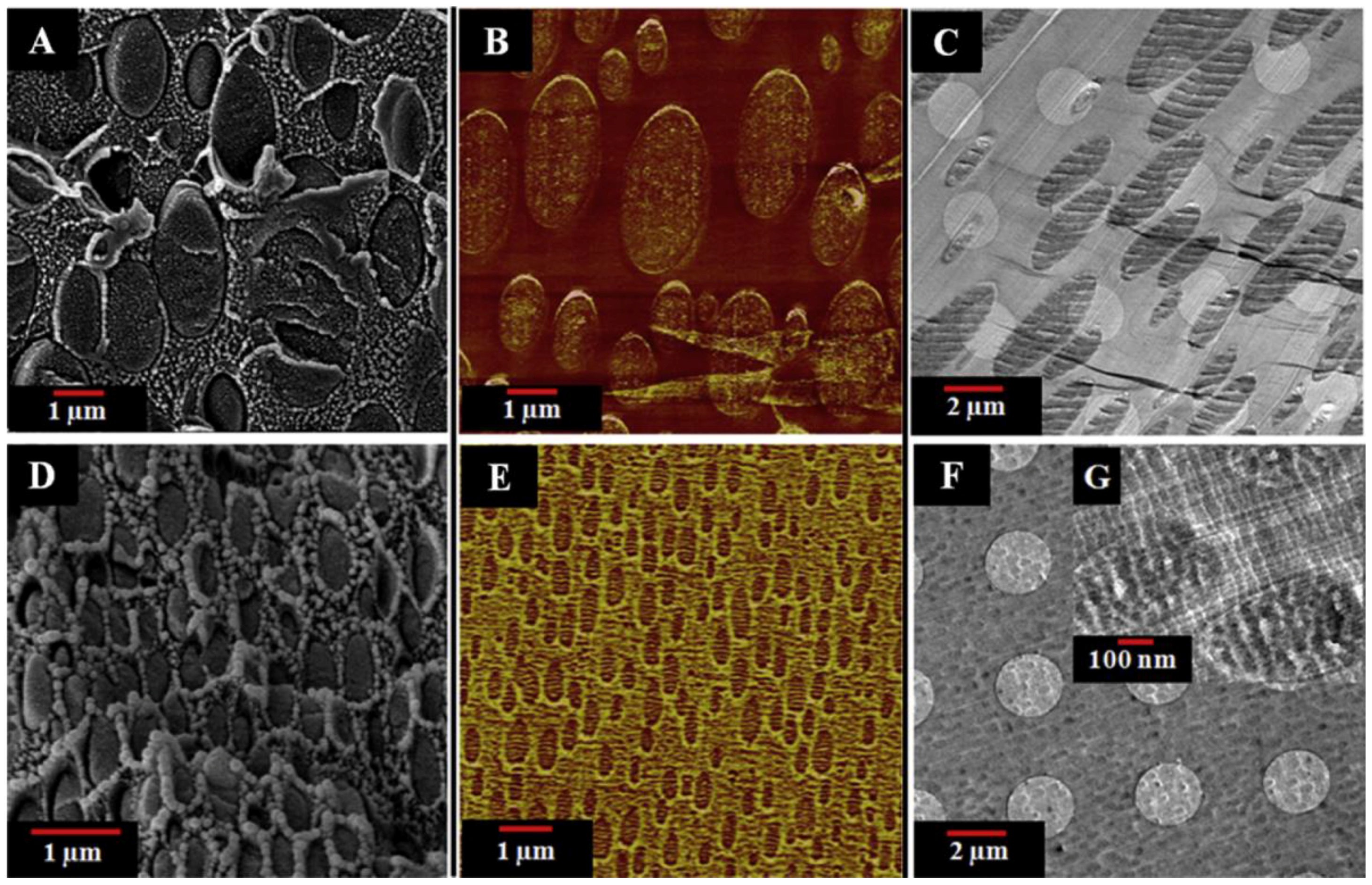

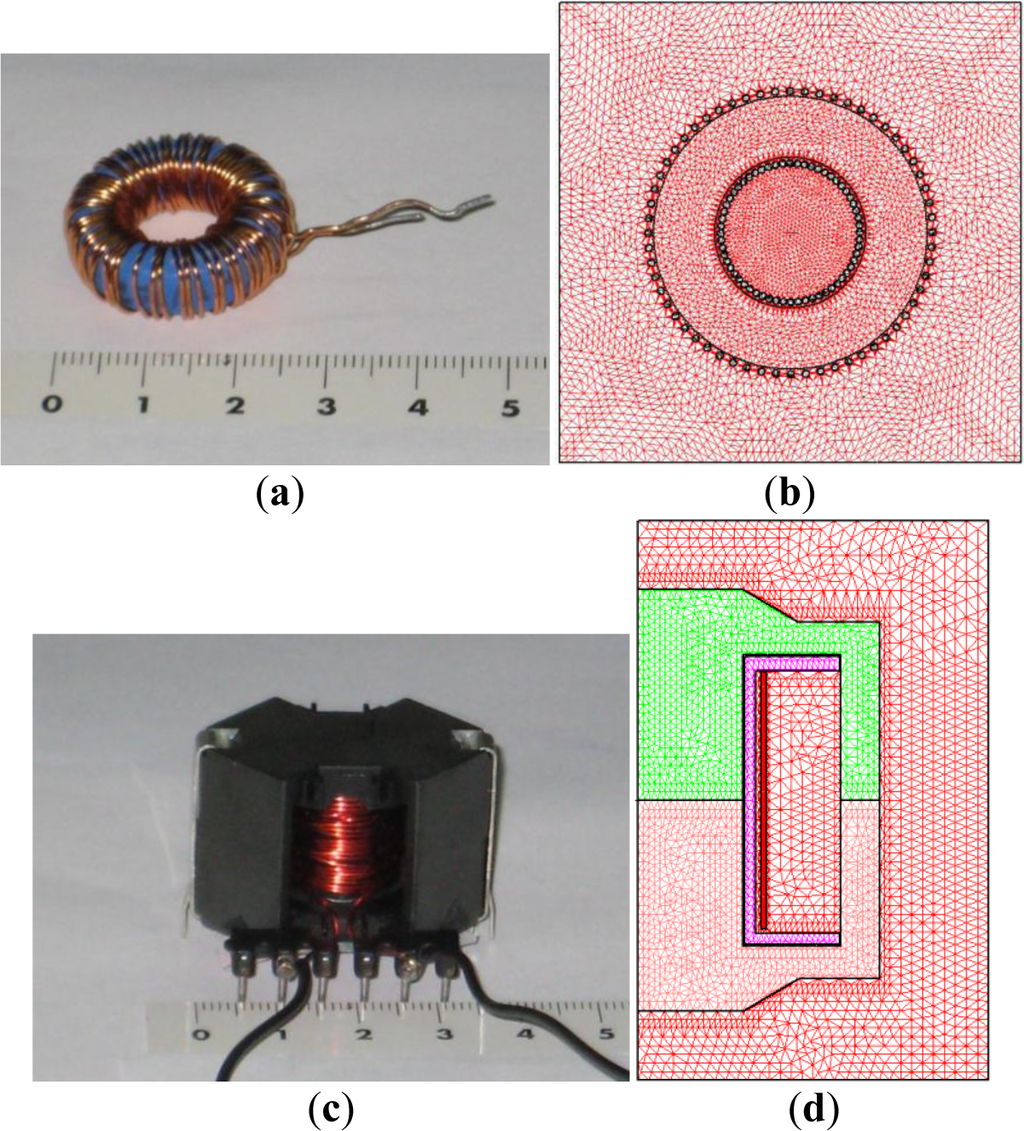

The contour scan strategies in laser powder bed fusion (LPBF) of Ti-6Al-4V were studied at the coupon level. These scan strategies determined the surface qualities and subsurface residual stresses. The correlations to these properties were identified for an optimization of the LPBF processing. The surface roughness and the residual stresses in build direction were linked: combining high laser power and high scan velocities with at least two contour lines substantially reduced the surface roughness, expressed by the arithmetic mean height, from values as high as 30 µm to 13 µm, while the residual stresses rose from ~340 to about 800 MPa. At this stress level, manufactured rocket fuel injector components evidenced macroscopic cracking. A scan strategy completing the contour region at 100 W and 1050 mm/s is recommended as a compromise between residual stresses (625 MPa) and surface quality (14.2 µm). The LPBF builds were monitored with an in-line twin-photodiode-based melt pool monitoring (MPM) system, which revealed a correlation between the intensity quotient I2/I1, the surface roughness, and the residual stresses. Thus, this MPM system can provide a predictive estimate of the surface quality of the samples and resulting residual stresses in the material generated during LPBF.

Materials An Open Access Journal from MDPI

Materials, Free Full-Text, test brain 140

Materials, Free Full-Text, morenting auto spray

Materials, Free Full-Text, passfeder 5mm

Materials, Free Full-Text

Free Download Construction Materials, Methods and Techniques Full Pages by madalynchwamadalynchwa - Issuu

:max_bytes(150000):strip_icc()/bill-of-materials-b4f384896bc34fd59179167b741ee852.jpg)

Materials, Free Full-Text, Carbon Felt

Buy Dental Materials (Full colour) Book Online at Low Prices in India

Metals, Free Full-Text, simulation unclogger

Materials, Free Full-Text

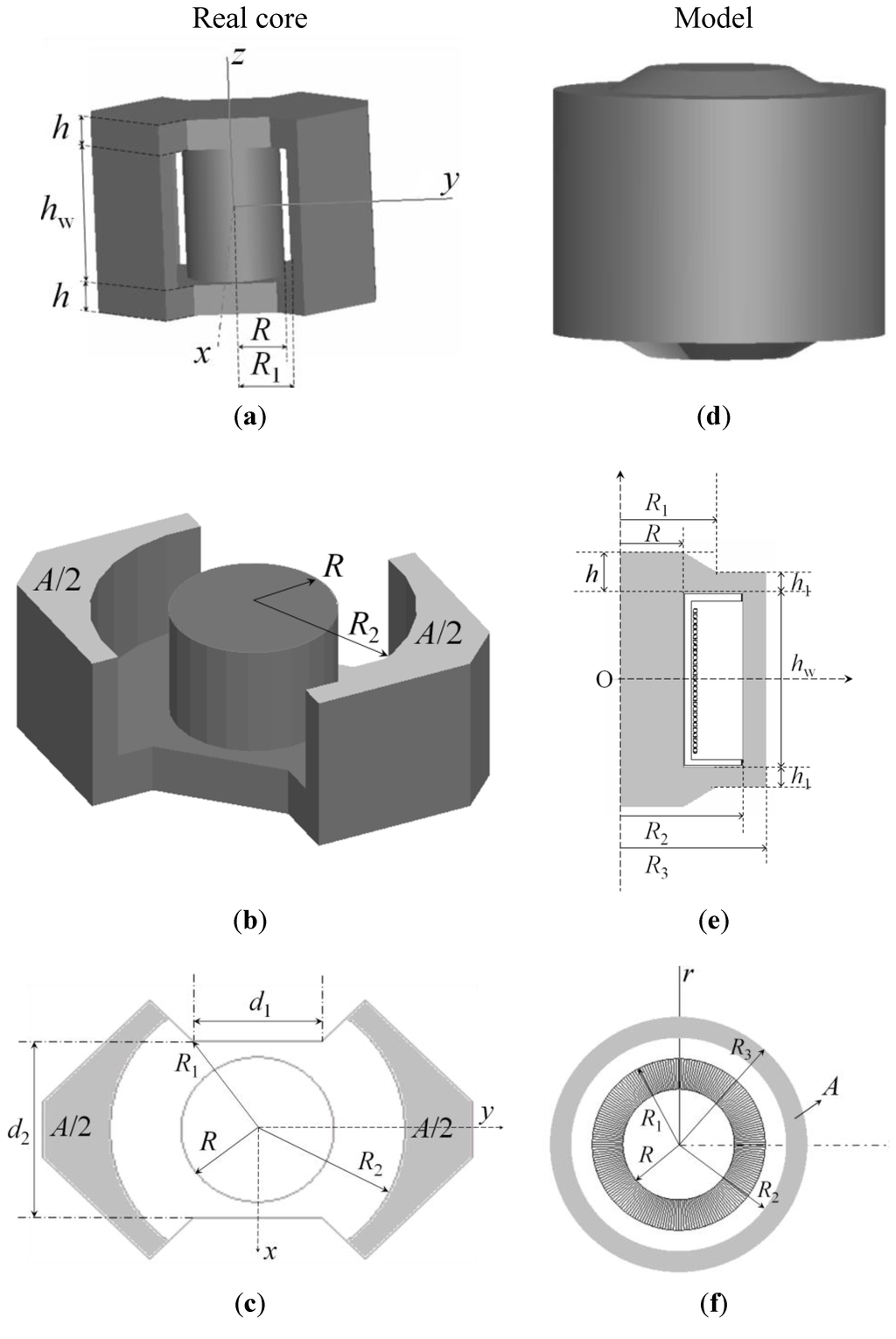

Materials, Free Full-Text, values mm2 laser

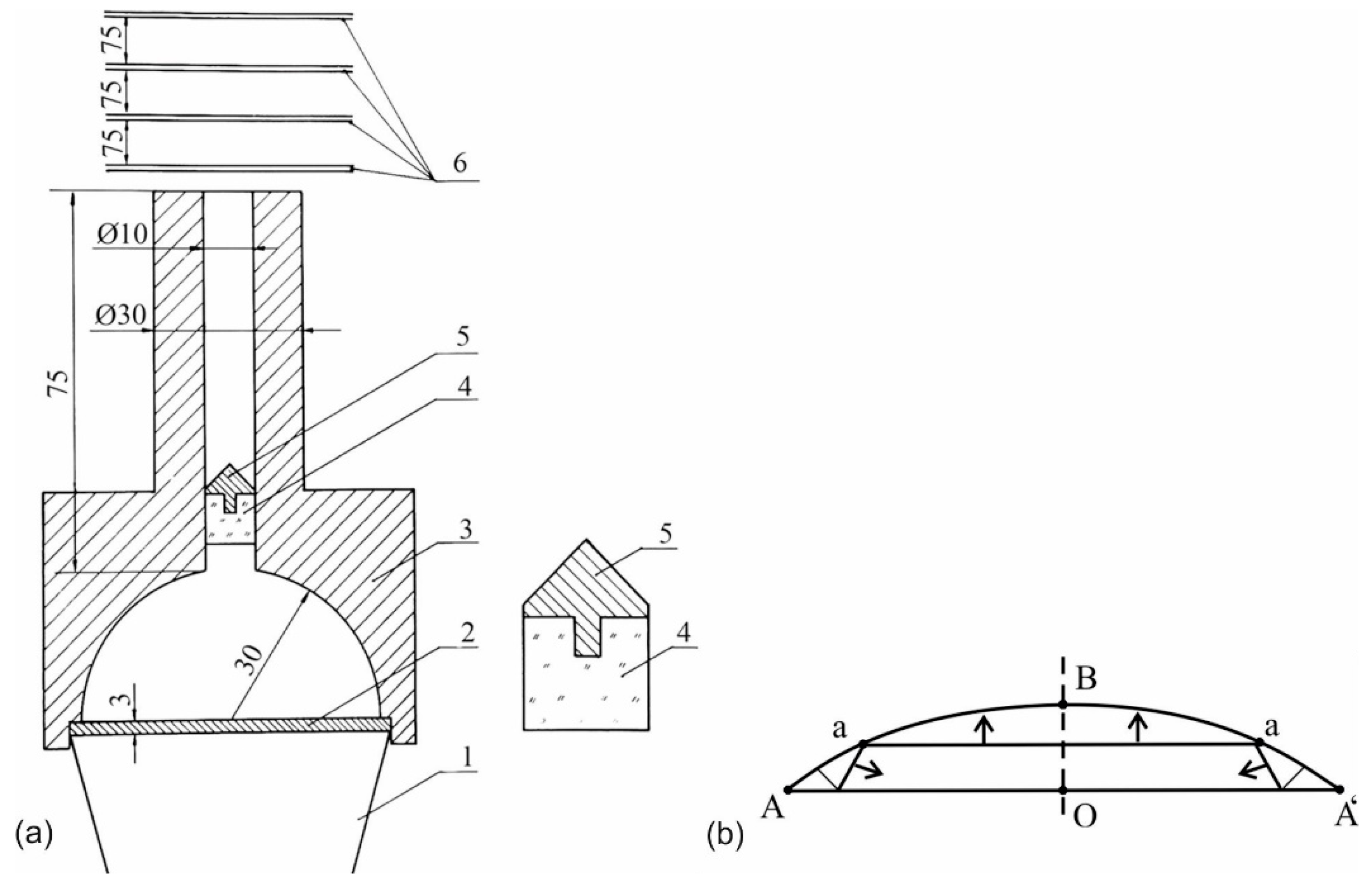

Q.Max 16-50mm Sheet Metal Punch to cut clean metric sized holes in

FREE gifts & price promise Plastics in Packaging — a Cradle to